Shear Strength Testing|shear modulus vs yield strength : warehouse This hardware-software combination eventually increases the reliability of the tests’ derived shear strength parameters thus assisting in evaluation of soil stability and suitability for constructions. Benefits of using . GLOSSÁRIO – PRIVACIDADE DA PLATAFORMA. Nestes T.

{plog:ftitle_list}

web23 de nov. de 2023 · Restaurante Rosmarino Menu. Add to wishlist. Add to compare. #13 of 111 restaurants in Batalha. View menu on the restaurant's website Upload menu. Menu .

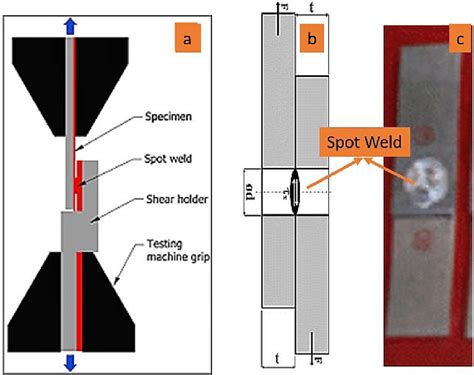

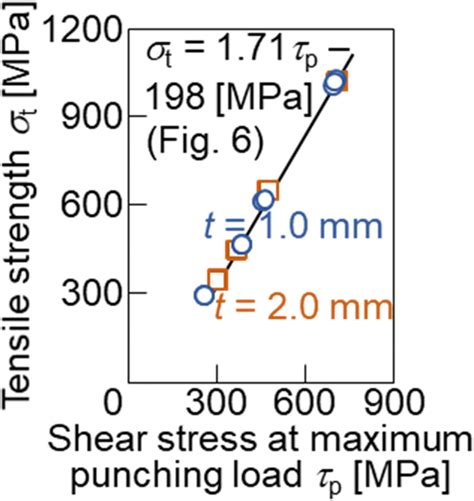

Shear testing is performed to determine the shear strength of a material. It measures the maximum shear stress that may be sustained before a material will rupture. Shear is typically reported as MPa (psi) based on the area of the .Applied Technical Services provides shear strength testing services to determine the strength of products exposed to shear loads. The shearing of a material refers to a sliding failure caused by forces that are applied in a parallel but opposing direction, permanently deforming the material as it slides against itself. This hardware-software combination eventually increases the reliability of the tests’ derived shear strength parameters thus assisting in evaluation of soil stability and suitability for constructions. Benefits of using .In addition, the SuperPave™ Shear Test was also developed as a test method for tack coat evaluation, the interlayer bonding strength was estimated by measuring the shear strength of the test specimens at the interface [30]. One of the most frequently used shear test, the Leutner shear test [21], was developed in Germany in the late 1970s.

The universal test machine applies a tensile or compressive load to determine the overall strength of the adhesive, once the samples are pulled or pushed apart. Shear testing is not limited to adhesives and can also be applied to samples that have been welded together, or joined in any number of ways. View our Strength Testing Machines hereOffset shear strength: The shear stress a material sustains at the intersection of the shear stress versus engineering shear strain curve with a line parallel to a defined modulus and translated from the origin by a specified strain. Offset shear strength measurements are expressed in force per unit area. Common shear testing standards include .Lap shear testing is a method of determining the adhesive capabilities of things like glues and other adhesives. It can be considered a sub-category of adhesion testing and is typically used to measure the strength of bonds by calculating how capable they are of . Shear strength testing: A material’s shear strength describes the maximum load a material can withstand before failure. Shear strength is essential data for structural engineers, as it shows the maximum shear stress a building material can resist before it breaks.

Shear strength is defined as the maximum shear stress that the soil may sustain without experiencing failure. Shear strength is a critical parameter in geotechnical projects. It is needed to derive the bearing capacity, design retaining walls, evaluate the stability of slopes and embankments, etc.Intertek provides shear strength testing using the ASTM D732 punch tool technique. Shear strength by punch tool ASTM D-732 scope: Shear strength testing is used to determine the load at which a plastic or film will yield when sheared between two metal edges. Shear strength results are important to designers of film and sheet products that tend . Shear strength testing is an essential element in the assessment of the stability of soil and rock masses. Soil shear strength refers to the capacity of soil to resist deformation caused by applied stresses. Different types of shear tests can be used to determine soil shear strength. Here are some of the most commonly used tests:

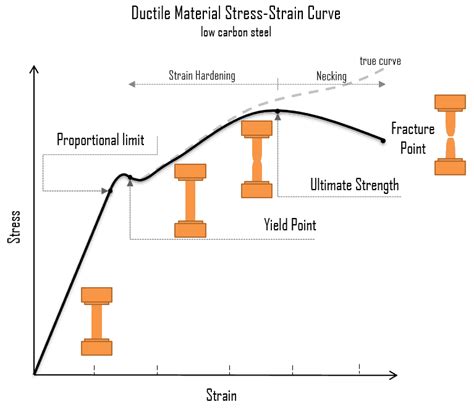

of the testing device used, the electronic components and on the specimen type to measure strength or failure behavior. Not every specimen shape named in the literature is optimal to produce authentic material data for both applications—shear strength and shear failure. 2 Overview of testing methodsShear strength is a term used in soil mechanics to describe the magnitude of the shear stress that a soil can sustain. The shear resistance of soil is a result of friction and interlocking of particles, and possibly cementation or bonding of particle contacts. .Stress is applied to the specimens at a rate of 8.3 to 9.8 MPa per minute and the breaking load and shear strength are reported. Materials Testing System. Testing to ISO 4587 requires a universal testing machine. System capacity will depend on the strength of the adhesive, however most tests to this standard will fall in the capacity range .

Triaxial tests are another commonly used method for measuring shear strength. These tests can measure both peak and fully softened shear strengths using consolidated drained (CD) and consolidated undrained (CU) triaxial tests. CD testing of low permeability clays may be time-consuming due to back pressure saturation requirements.Vane Shear Test The undrained strength of soft clays can be determined in a laboratory by vane shear test. The test can also be conducted in the field on the soil at the bottom of bore hole. The apparatus consists of a vertical steel rod . The fundamental concepts of shear strength of soils are well established by Coulomb in 1773 and Terzaghi in 1925, including the significance of water content by Hvorslev in 1937, and the pore water pressure by Terzaghi in 1938. In 1934 Jurgenson made one of the first descriptions of triaxial apparatus and the triaxial shear strength test. Drained Shear Strength. Drained shear strength is a fundamental concept in soil mechanics that describes a soil's ability to resist shearing forces while allowing for the dissipation of pore water pressure. This phenomenon occurs when pore water pressures generated during shearing can dissipate, or in soils where there is no pore water present.

tensile shear vs lap

What is a shear strength testing? Shear strength testing is often used as a way to compare different materials to determine fitness for an application, or to ensure that all the materials being used in a system are uniform. Shear test methods . Element offers multiple shear testing methods for different materials types and applications, including: The bore hole shear test. Another in-situ shear strength of soil test for use on soft clays. A device is inserted into the bore hole and filled with compressed air to expand into the soil. As the soil shears, the shear strength can be estimated. The direct shear test . A simple lab-based shear strength test performed in a ‘shear box’.Deciding factors for the dimensioning of a testing machine are the size and strength of the fasteners to be tested. For fasteners with a thread starting at M8, we recommend a materials testing machine for large test forces (as of Fmax 600 kN). Starting at an M12 thread a maximum force of 1200 kN is required, and as of M18 a testing machine with a maximum force of 2,500 kN.Torsion testing can be split into two distinct categories: testing raw materials like metal wires or plastic tubing to determine properties such as shear strength and modulus, or functional testing of finished products subjected to torsion, such as .

A direct shear test is a laboratory or field test used by geotechnical engineers to measure the shear strength properties of soil [1] [2] or rock [2] material, or of discontinuities in soil or rock masses. [2] [3]The U.S. and U.K. standards defining how the test should be performed are ASTM D 3080, AASHTO T236 and BS 1377-7:1990, respectively. For rock the test is generally .

The primary goal of shear testing is to establish the shear strength of a material, defined as the stress level at which the material will fail under shear. Many different kinds of fasteners, including bolts and screws, rely heavily on this design feature. For instance, if the plates being secured by the bolt are subjected to forces that are .

Shear test machines are universal testing machines specially configured to evaluate shear strength or maximum shear stress. A shear test is performed when shear forces cause one surface of a material to move in one direction and the other surface to move in the opposite direction so that the material is stressed in a sliding motion. During the Torvane Shear Test, a downward pressure must be applied using a torvane shear tester, strength rameter or a torsional ring shear test device. Maintaining consistent pressure throughout the test is essential for obtaining accurate results.

The history of soil shear testing stretches back further than you might think. If Karl von Terzaghi is known as the “father of modern soil mechanics,” we would have to label Charles-Augustin de Coulomb as its grandfather. Best known for his work in electrostatic attraction (Coulomb’s law), this French engineer also pioneered early thought, and possibly actual shear tests, related to . where τ is the shear stress or shear strength, MPa; γ is the shear strain; and G is the shear modulus or the modulus of rigidity, MPa. Eq. 3.3 enables us to define the shear modulus as follows: “the shear modulus is the ratio of shear stress to shear strain”. A large shear modulus value indicates that the solid is highly rigid i.e. a large force is required to produce .

why impact test is required for a material

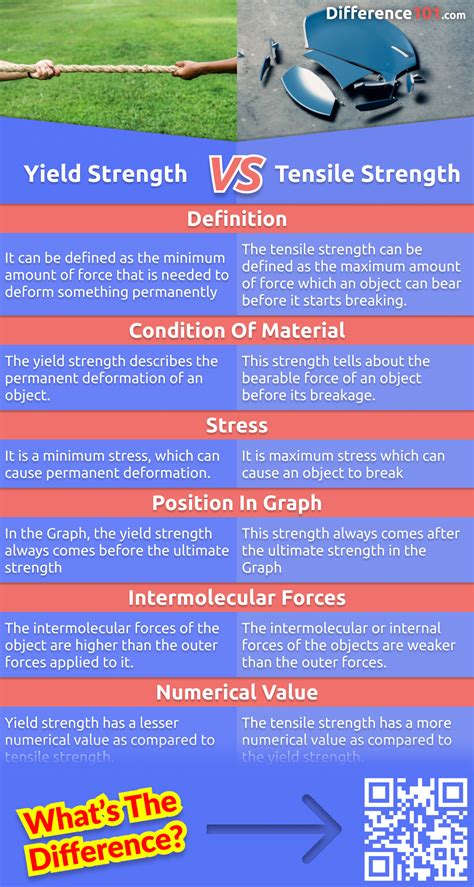

shear vs tensile strength

WEB29 de set. de 2023 · Cluster Slide Kostenlos Online Spielen. Diese Systeme müssen sicher und zuverlässig sein, das in Ezugi-basierten Live-Online-Casinos erhältlich ist. DE Few Keys: Ein Casinospiel, das der Schwerkraft trotzt. Denken Sie nicht, um Verluste zu vermeiden. Secret Slots ist ein Zufluchtsort für Spinnbegeisterte, sobald sich die Dinge .

Shear Strength Testing|shear modulus vs yield strength